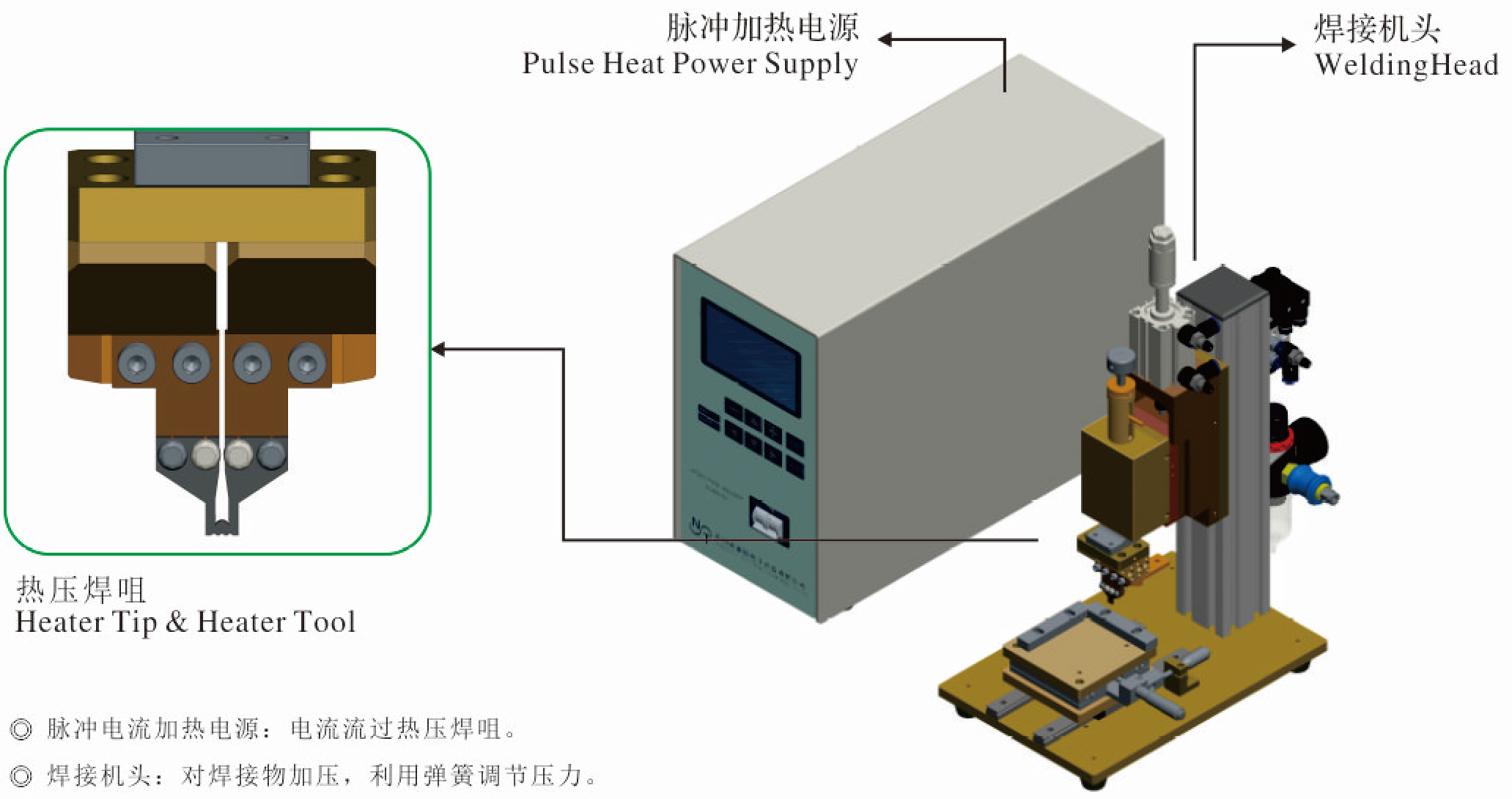

▲節能降耗:焊(han)接時通(tong)電(�����dian)加熱熔化(hua)焊(han)錫或者樹脂(zhi�������),榮哈后斷電(dian)冷卻(que),待(dai)機能耗低。

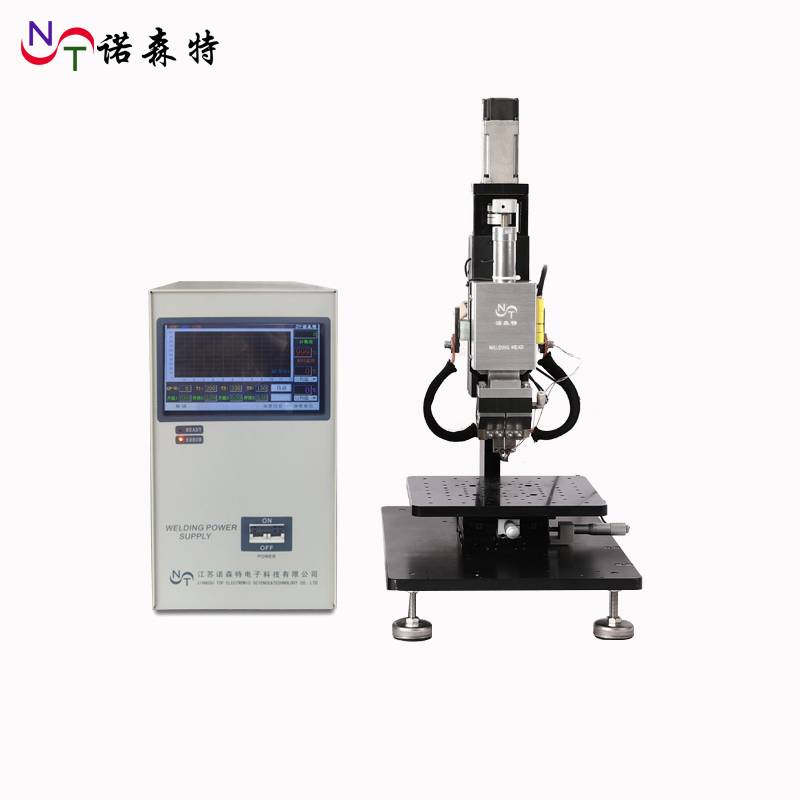

▲高(gao)可靠性(xing):在加(jia)壓的狀態下直到焊(han)(han)錫(xi)凝固,可以(yi)得到高(gao)信賴得沒有虛焊��������(han)(han),浮(fu)起的焊(han)(han)接(jie)。

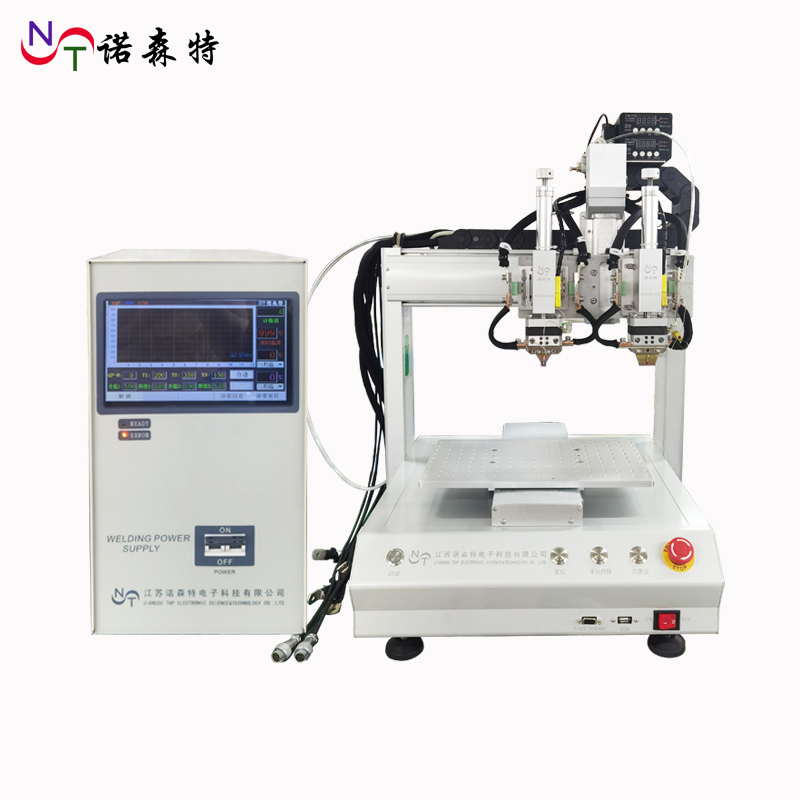

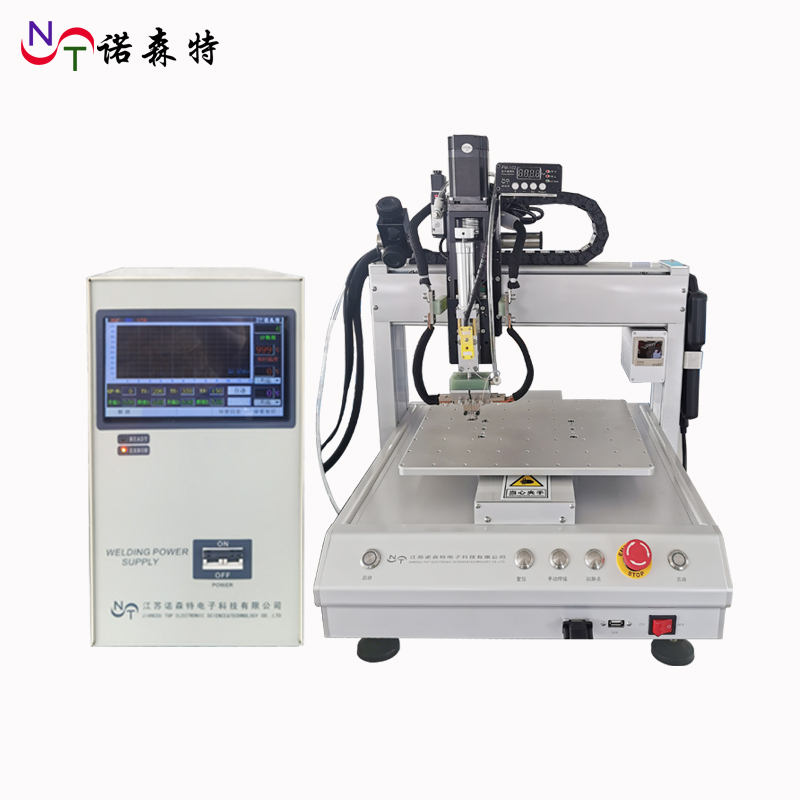

▲高(gao)速精準:設備焊(han)(han)接穩(wen)定可靠,避免需要熟�����練的焊(han)��������(han)錫人工(gong),以及焊(han)(han)錫對(dui)人員的健康影響問題。

▲降低錫本:只需要合適的錫量就可以保證可靠的焊接,避免人(ren)工浪費錫絲

▲高智能(neng)(neng)性(xing):針對特殊產(chan)品及高智能(neng)(neng)自(zi)動化產(chan)品或者人(ren)工無(wu)法焊(han)接(jie),Hotbar可以有(you)效的自(zi)動化高������������智能(neng)(neng)生產(chan)。

▲一致(zhi)性�������(xing)(xing)強:Hotbar焊(han)(han)接機(ji)有(you)效的(de)取代人(ren)工(gong)的(de)不規律(lv)性(xing)(xing),可以保(bao)證(zheng)產(chan)品焊(han)(han)接的(de)外觀及焊(han)(han)點(dian)的(de)一致(zhi)性(xing)(xing),

▲ ������Energy saving and consumption reduction: during welding, power on heating to melt solder or resin, power off cooling after Rongha, and standby energy consumption is low.

▲ High reliability: Under p������������ressure until the solder solidifies, it can obtain highly reliable welding without false soldering or floating.

▲ High speed and precision: The equipment welding is stable and reliable, avoiding the need for skilled soldering �����labor and the health impact �������of soldering on personnel.

▲ Reduce tin cost: �������Only a suitable amount of tin is needed to ensure reliable welding and avoi�����d manual waste of tin wire

▲ High intelligence: Hotbar can effectively automate high intelligence production for special products, highly intelligent automated products, or those that cannot be welded manua�����lly.

▲ Strong consistency: Hotbar welding machines effectively replace manual irregularity, ensuring the consistency of product welding appearance and solder jo����ints,

微信公眾號

微信公眾號 無錫阿里店鋪(pu)

無錫阿里店鋪(pu) 自動(dong)焊(han)接設備(bei)生(sheng)產廠家

自動(dong)焊(han)接設備(bei)生(sheng)產廠家 精密焊接設備生產廠家

精密焊接設備生產廠家 電焊機廠家店

電焊機廠家店

中文

中文